Printed Circuit Board Manufacturing

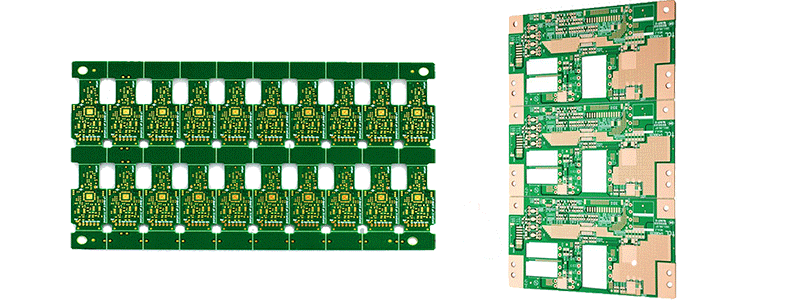

Standard PCB(Printed Circuit Board) manufacturing(Production Run PCB not PCB prototype to test electronic design) refers to full manufacturing service of Printed Circuit Boards that use FR4 as the base materials. Standard PCBs are the most commonly used type of PCBs. With Standard PCB, fiberglass-reinforced epoxy-laminated sheets are used as the backbone material.

Standard PCB(Printed Circuit Board) Manufacturing or PCB Prototype

It is essential to understand when to make use of Prototype Services and when to go for Standard PCB manufacturing. Prototype PCB services are used when developing a new project. With Prototype PCB Services, you can test your designs, check for flaws and understand what adjustments need to be made. Prototype PCB services are usually made in small quantity to avoid cost in case of errors. Hence, PCB prototype services allow you to test run your designs and adjust the errors before commencing full production.

Standard PCB manufacturing services involve the production of the actual PCBs you will use in your applications. It takes a longer number of days because of the use of more complex materials and fabrication processes.

Standard PCB(Printed Circuit Board)Manufacturing with PCBdoing

Get your top of the range Standard PCB at PCBdoing. We follow the best practices in ensuring that your boards are fully functional and will fit your applications perfectly. Over the years, we have manufactured Standard PCBs for various industries from the telecommunications industry to the Healthcare industry. Our Standard PCB have advanced features capable of giving your applications the quality it deserves. Here is a full list of the capabilities of our Standard PCB.

Why Choose PCBdoing

As professionals in the manufacture of PCB, we offer various qualities that make us different.

Quality:We never joke with the quality of PCBs. Our clients over the years trust our services to deliver the best always. Our Standard PCBs are also certified in compliance with ISO 9001:2008 standards. In addition, our quality control officers ensure the standards are met throughout the stages of production, from manufacturing to packaging.

Affordable Prices: We offer the best prices for standard PCBs on the market. Even at the highest quality, our PCBs are very affordable. We can also always negotiate when you order large quantities of Standard PCBs.

Customer Satisfaction: We ensure our customers are always happy with our products. Hence, we'll always listen to your instructions and complaints if there are any.

Getting a quote had never been this easy. To get your quote, simply submit your PCB specifications and requirements and we will respond!

Also, if you have any enquiries, you can contact us and one of our experts will get back to you. We look forward to giving you the best

| Feature | Capability |

| Quality Grade | Standard IPC 2 |

| Number of Layers | 1 - 32layers |

| Order Quantity | 1pc - 10,000,000 pcs |

| Build Time | 2days - 5weeks (Expedited Service) |

| Material | FR-4 Standard Tg 150°C, FR4-High Tg 170°C, FR4-High-Tg 180°C, FR4-Halogen-free, FR4-Halogen-free & High-Tg |

| Board Size | Min 6*6mm | Max 600*700mm |

| Board size tolerance | ±0.1mm - ±0.3mm |

| Board Thickness | 0.4mm - 3.2mm |

| Board Thickness Tolerance | ±0.1mm - ±10% |

| Copper Weight | 0.5oz - 6.0oz |

| Inner Layer Copper Weight | 0.5oz - 2.0oz |

| Copper Thickness Tolerance | +0μm +20μm |

| Min Tracing/Spacing | 3mil/3mil |

| Solder Mask Sides | As per the file |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Silkscreen Sides | As per the file |

| Silkscreen Color | White, Blue, Black, Red, Yellow |

| Surface Finish |

HASL - Hot Air Solder Leveling Lead Free HASL - RoHS ENIG - Electroless Nickle/Immersion Gold - RoHS ENEPIG - Electroless Nickel Electroless Palladium Immersion Gold - RoHS Immersion Silver - RoHS Immersion Tin - RoHS OSP -Organic Solderability Preservatives - RoHS |

| Min Annular Ring | 3mil |

| Min Drilling Hole Diameter | 6mil, 4mil-laser drill |

| Min Width of Cutout (NPTH) | 0.8mm |

| NPTH Hole Size Tolerance | ±.002" (±0.05mm) |

| Min Width of Slot Hole (PTH) | 0.6mm |

| PTH Hole Size Tolerance | ±.003" (±0.08mm) - ±.006" (±0.15mm) |

| Surface/Hole Plating Thickness | 20μm - 30μm |

| SM Tolerance (LPI) | .003" (0.075mm) |

| Aspect Ratio | 1.10 (hole size: board thickness) |

| Test | 10V - 250V, flying probe or testing fixture |

| Impedance tolerance | ±5% - ±10% |

| SMD Pitch | 0.2mm(8mil) |

| BGA Pitch | 0.2mm(8mil) |

| Chamfer of Gold Fingers | 20, 30, 45, 60 |

| Other Techniques |

Gold fingers Blind and Buried Holes peelable solder mask Edge plating Carbon Mask Kapton tape Countersink/counterbore hole Half-cut/Castellated hole Press fit hole Via tented/covered with resin Via plugged/filled with resin Via in pad Electrical Test |