Flexible PCB Manufacturing

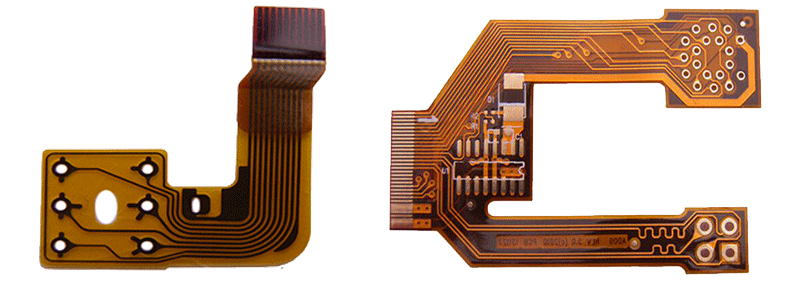

What is Flexible PCB?

Flexible PCB - also referred to as Flexible Printed Circuit Board, Flexible Circuits, Flex prints - are used in interconnecting electronic devices. Flex PCBs have printed conductive circuit patterns covered by thin polymer coating for protection. Flex PCBs, unlike rigid PCBs, are made to fit electronic devices.

Flexible Printed Circuit Categories and Structure

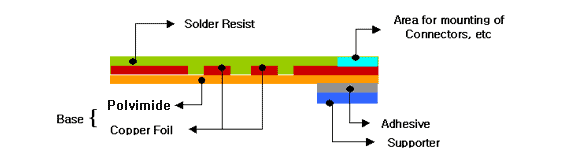

Single Sided Flexible Printed Circuit

Dual Access Single Sided Flexible Printed Circuit

![]()

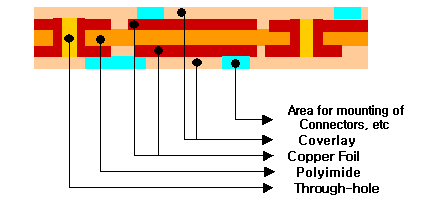

Double Sided Flexible Printed Circuit

Multilayer Flexible Printed Circuit

Benefits of Using Flex PCBs

The benefits of Flex PCBs are numerous. Some of the benefits include:

Flexibility during Installation

Flex PCBs offer a whole lot of freedom while installing the components of devices. Their flexibility allows for interconnection between two or more planes. Requiring less than 10% of space and weight of a circuit board assembly, Flex PCBs usage leads to an incredible space management and reduce the weight of the devices.

Higher Airflow

Because they consume very little space, Flex PCBs allow for a higher flow of cool air through an electronic device.

Maximum System Reliability

The main cause of problems with circuit boards is with interconnections. With Flexible Printed Circuit Boards, interconnections are greatly reduced, hence, there are fewer solder points and contacts. Therefore, the chances of system failure are greatly reduced.

Reduced Cost and Assembly Time

With Flexible circuit boards, there's reduced soldering, routing, and wrapping. This leads to a huge reduction in cost. Also, with a Flex PCBs, there’s reduced need for manual labor, which reduces the chances of production errors and wiring errors. Ultimately, assembly time is kept low and costs are reduced.

Enhanced Functions

Flex PCB are exceptionally suitable for use in moving parts of a device. Also, they have high thermal capabilities and can withstand extreme temperatures in addition to offering a higher resistance to chemicals and radiations.

Application

Flexible Printed Circuit Boards are widely used in various devices that can be categorized as:

Static: These are applications that require Flex PCB to act only as a circuit without the need for movement. Examples include Calculators, Airbag system, Cameras etc.

Dynamic: In dynamic applications, the Flexible circuits are continuously moved/flexed during usage. Examples of dynamic applications include Flip cell phones, Laptops etc.

Why Get Your Supply of Flex PCBs from PCBdoing?

Here are reasons why you should purchase your Flexible PCB from us.

Quality

At PCBdoing, we specialize in manufacturing quality PCBs for various types of industry. We are a household name in the electronics industry due to our unshakable commitment to manufacturing only quality flexible PCBs. Prior to supplying your PCBs, we make extra effort to check for any errors in design. At PCBdoing, quality is our watchword.

Custom Flexible PCB

We also specialize in the production of custom Flex PCBs. We understand that every electronic device is unique and will require a custom Flexible PCB. With our experts, we produce quality Flex PCBs that are designed to suit your requirement. PCBdoing can manufacture any Flex PCB in any industries, from the health industry to the telecommunication industry.

Affordable Prices

Despite the quality of the Flex PCBs we manufacture, our Flex PCBs are affordable. For quality Flex PCBs, we guarantee you the best prices!

Contact Us for a Quotation or For More Information

You can submit a custom request and get a price quote. Also for any additional information, do not hesitate to contact us. We’ll respond immediately!

| Feature | Capability |

| Quality Grade | Standard IPC 2 |

| Number of Layers | 1 - 8layers |

| Order Quantity | 1pc - 10000+pcs |

| Build Time | 2days - 5weeks |

| Material | DuPont PI, Domestic Shengyi PI |

| Board Size | Min 6*6mm, Max 406*610mm |

| Board Thickness | 0.1mm - 0.8mm |

| Copper Weight (Finished) | 0.5oz - 2.0oz |

| Min Tracing/Spacing | 3mil/3mil |

| Solder Mask Sides | As per the file |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Solder-stop coating---Soldermask oil | Green, White, Blue, Black, Red, Yellow |

| Solder-stop coating---Coverlay | PI and PET film |

| Silkscreen Sides | As per the file |

| Silkscreen Color | White, Black, Yellow |

| Surface Finish | HASL - Hot air solder leveling Lead - free HASL - RoHS ENIG - RoHS Immersion Tin - RoHS OSP - RoHS |

| Min Annular Ring | 4mil |

| Min Drilling Hole Diameter | 8mil |

| Min. hole size---Drilling (PTH) | 0.2mil |

| Min. hole size---Punching (NPTH) | 0.5mil |

| Tolerance of dimension | ±0.05mm |

| Other Techniques | Peelable solder mask Gold fingers Stiffener (only for PI/FR4 substrate) |