Rigid Flex PCB Manufacturing

Rigid-Flex PCB Manufacturing

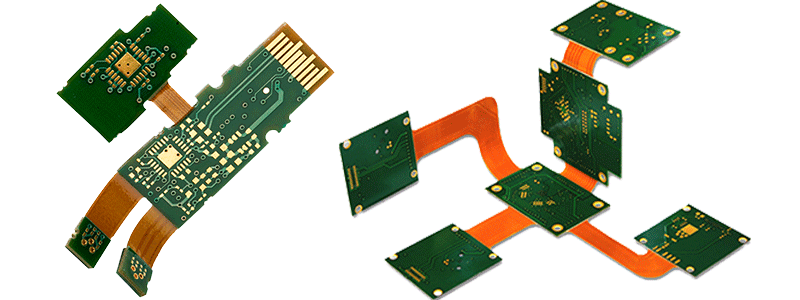

A Rigid-Flex PCB is a type of Print Circuit Board where two different types of PCB are connected. It involves the use of a solid or stable substrate (fibre glass) and flexible or a dynamic substrate (polyimide) with adhesive and other conductive materials such as copper or aluminium. However, these two substrates and the conductive materials can be structured in a way that brings about a light-weight and unique shaped PCB board dimensions such as curved shape, arc shape etc.

Benefits of Rigid-Flex PCB

Portability: in a complex design whereby small size is required to contain its complexity, rigid-flex PCB is an option as the two substrate gives room for the bending and orientation in which small size is achieved thereby making it conform to design.

Cost Reduction: As suppose to the large boards in other PCB types, two or more boards can be constricted into light-weight, single board, whereby connectors which are supposedly present in a single board are eliminated and thus brings about a drastic decrease in cost.

Easy-to-Test: Rigid-Flex PCBs are very easy to test. Hence, they are very suitable to use as Prototype PCB.

Ruggedness: With the evolution of rigid-flex PCB, boards can withstand tough environment such as high temperature, high signal generation, high electronic magnetic transmission etc. All these are achieved through the use of a flexible substrate e.g. Polyimide.

Quality: The use of layer lamination ensures that the utmost quality is maintained.

Quality and Affordable Rigid-Flex PCB at PCBdoing

Therefore, as an engineer or an electronic device production company who is after simplicity, light-weight but sophisticated board designs check out rigid-flex PCB. Hence, at PCBdoing the following attributes distinguish us from other competitors in the business:

Here, at pcbdoing we execute one to twenty-four layer Rigid-Flex PCB for your print circuit board (PCB) depending on your choice with on-time delivery.

At Pcbdoing, when you repeat an order, tool charging will not be included in your Bill payment.

There is no limitation to the smallest order quantity you can make at PCBdoing.

We guarantee the quality of the components used in manufacturing your Rigid-Flex PCB. In addition to using quality components, we ensure that your PCBs are well assembled correctly, properly packed and checked before supply.

Get Your Instant Quote Now

To get an instant quote, send us your design file and we’ll respond with your quote immediately! Make a deal with us today and you will be convinced you did.

| Feature | Capability |

| Quality Grade | Standard IPC 2 |

| Number of Layers | 2 - 24layers |

| Order Quantity | 1pc - 10000+pcs |

| Build Time | 2days - 5weeks |

| Material | DuPont (PI25UM), FR4 |

| Board Size | Min 6mm x 6mm Max 457mm x 610mm |

| Board Thickness | 0.6mm - 5.0mm |

| Copper Weight (Finished) | 0.5oz - 2.0oz |

| Min Tracing/Spacing | 3mil/3mil |

| Solder Mask Sides | As per the file |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Silkscreen Sides | As per the file |

| Silkscreen Color | White, Black, Yellow |

| Surface Finish | HASL - Hot air solder leveling Lead - free HASL - RoHS ENIG - RoHS |

| Min Annular Ring | 4mil |

| Min Drilling Hole Diameter | 8mil |

| Impedance control | ±10% |

| Other Techniques | HDI Gold fingers Stiffener (only for PI/FR4 substrate) |